RINSERS FOR EMPTY CONTAINERS

GG75

Machine suitable for cleaning empty containers (tinplate cans, glass jars, glass bottles, plastic containers).

Range of containers : diameter 30 to 160 mm – height 50 to 280 mm

Different treatments available (by air – steam – hot water)

Max. speed 12.000 with 500cc containers

TECHNICAL DATA

Electric consumption 4,5 kW

Air consumption 100NL/min at 3 bar

Steam consumption 80 kg/h a 3 bar

Overall dimensions 3600x1000xH.2000mm

Weight 500 kg

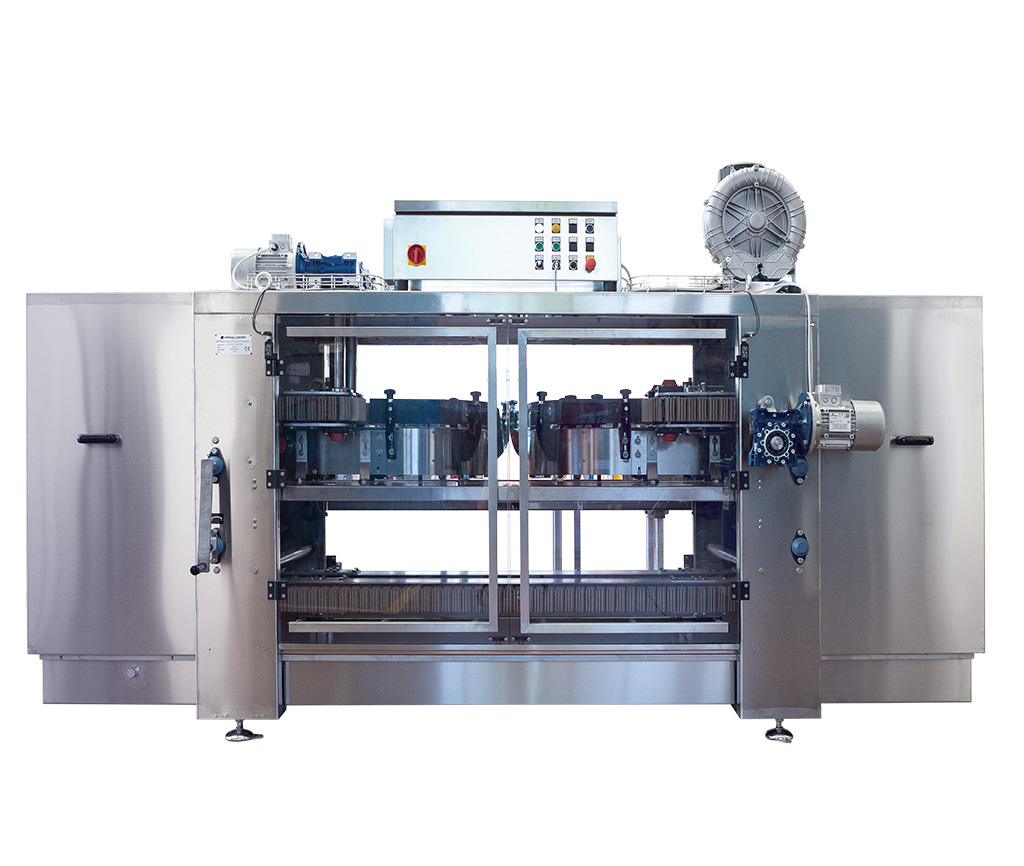

GG76

Machine suitable for cleaning empty containers (tinplate cans, glass jars, glass bottles, plastic containers).

Range of containers : diameter 30 to 160 mm – height 50 to 280 mm

Different treatments available (by air – steam – hot water)

Max. speed 24.000 with 500cc containers

TECHNICAL DATA

Electric consumption: 10 kW

Air consumption: 60 Nl/min at 2 bar

Steam consumption 400kg/h at 4 bar

Overall dimensions: 5900x1000xH 2100 mm

Weight: 1200 kg

WASHING MACHINES FOR FULL CONTAINERS

Washing machines for full containers completely made of Aisi 304 stainless steel available in two versions:

GG16

Continuous washing machine, featuring three phases, for cans, plastic containers, glass jars and bottles with 200mm max diameter and 300mm max height.

The machine is completely made of Aisi 304 stainless steel.

The process consists of three phases: washing, rinsing and draining

Max. speed 12.000 cph with 500cc containers

TECHNICAL DATA

Installed power : 10KW

Dimensions: 6000 X 700 X h working height level 1000+- 50 mm

Consumption of dry saturated steam at 2-4 bar pressure: 100 Kg/h.

Air consumption : 5 Nl/1” at machine start– pressure 6 bar

Water consumption: 200 litres each tank when water is totally replaced

GG08

Continuous washing machine, featuring two phases, for containers with 40 ÷ 200 mm diameter

The machine is completely made of Aisi 304 stainless steel.

The process consists of two phases: washing and draining

Max. speed: 5.000-6.000 cph with 500cc containers

TECHNICAL DATA

Installed power: 6 kW

Dimensions: 3000 x 550 x 1400 mm

Steam consumption: 40 kg/h