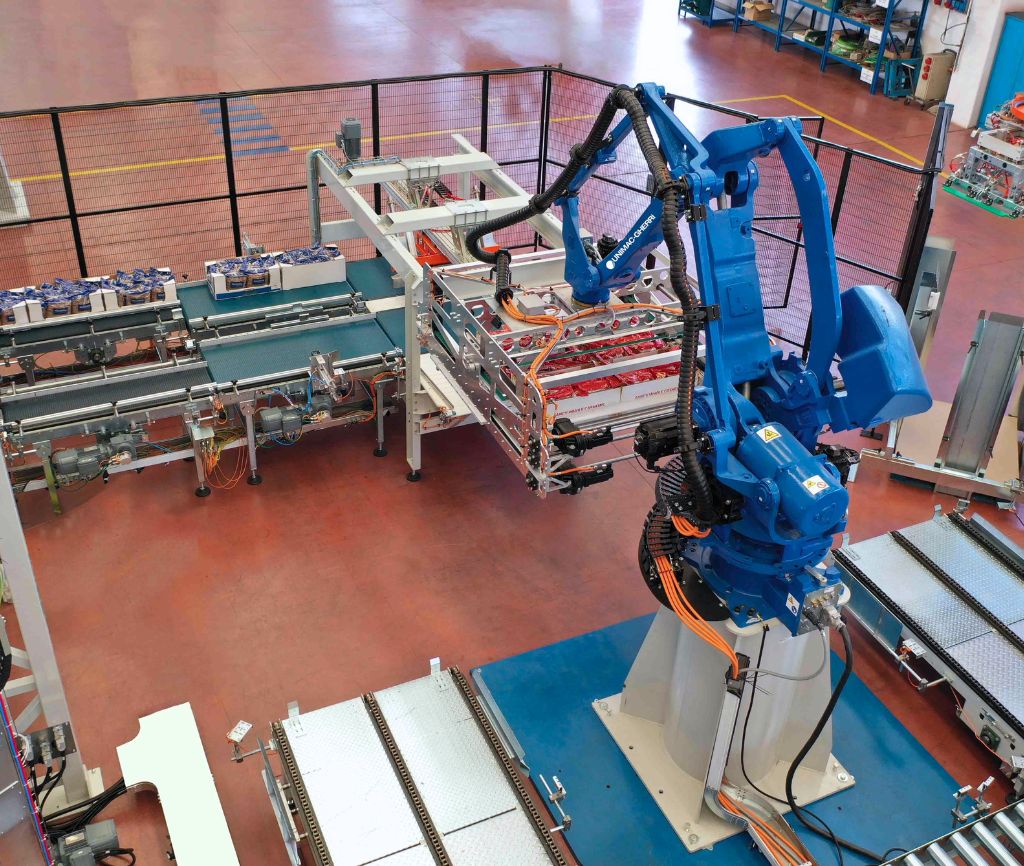

UNIMAC-GHERRI robotic palletizers are the ideal solution to automate the palletizing process of boxes and bundles in industrial environments. Designed for maximum flexibility, our systems automatically palletize boxes of any type, size, or weight, with an output of up to 50 boxes or bundles per minute.

Thanks to advanced robotic technology, our robotic palletizers ensure high precision, reduced cycle times, and maximum operational safety. Their compact and modular design allows for easy integration into existing packaging lines, optimizing available space and increasing overall production efficiency.

We also develop customizable gripper heads, designed according to the product to be palletized and the required capacity.

Technical Features:

- Palletizing speed: up to 50 boxes/bundles per minute

- Packaging types handled: boxes and bundles of various shapes, sizes, and weights

- Layout configurations: floor-level or elevated

- Capability to handle multiple palletizing bays

- Full customization based on customer requirements

- Interchangeable gripper heads, available in multiple variants:

- Paddle head (single pick or multi-row pick)

- Vacuum head (single, multi-row, or full-layer pick)

- Comb head (single or multi-pick)

- Belt head (full-layer pick)

- Customizable box/bundle preparation system, floor-level or elevated

Key Benefits:

- Automatic empty pallet feeding system

- Roller conveyors and diverters for handling full/empty pallets

- Automatic interlayer sheet management system

- Tailor-made solutions for complex layouts