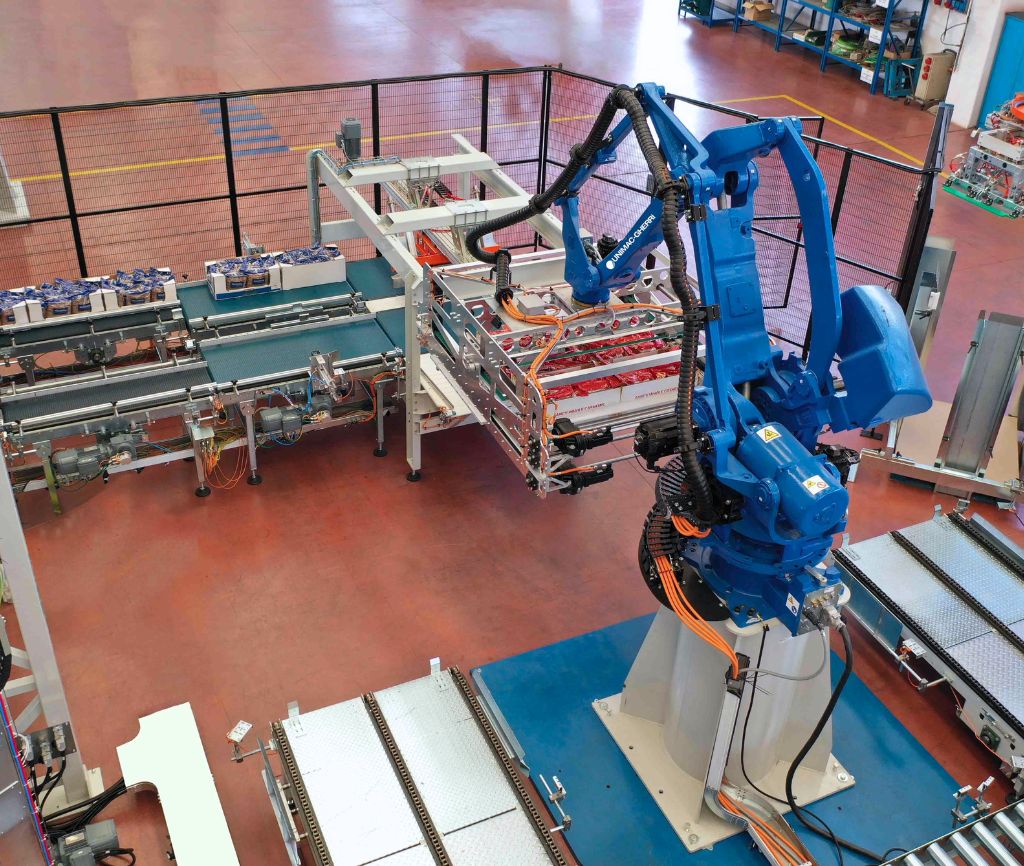

UNIMAC-GHERRI robotic palletizers are the ideal solution to automate the palletizing process of boxes and bundles in industrial environments. Designed for maximum flexibility, our systems automatically palletize boxes of any type, size, or weight, with an output of up to 50 boxes or bundles per minute.